Widely used to Normal cooling and heating in such industries as dairy, brewage, beverage, food, etc. Heating and cooling in pharmaceutical industry.

Tel:008618367778783 Email:sales@wzhongan.com

Plate heat exchanger:

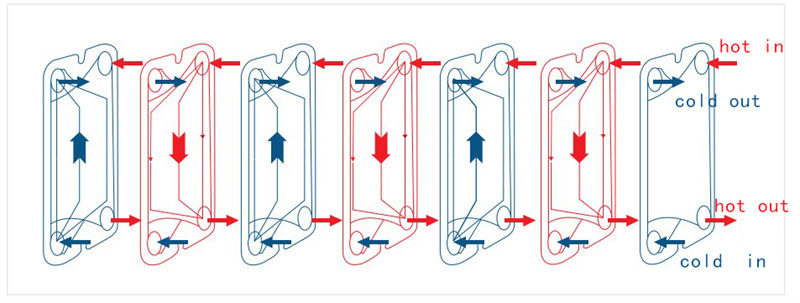

Plate heat exchanger is a new type of high efficiency heat exchanger which is composed of a series of metal sheets with a certain corrugated shape. Thin rectangular channels are formed between various plates, through which heat is exchanged. Plate heat exchanger is an ideal equipment for liquid - liquid and liquid - steam heat exchange. It has the characteristics of high heat exchange efficiency, small heat loss, compact and light structure, small space needed, convenient installation and cleaning, wide application, long service life and so on. Under the same pressure loss, its heat transfer coefficient is 3-5 times higher than the tubular heat exchanger,the occupied area is one-third of the tubular heat exchanger, and the heat recovery can be up to more than 90%.

Features:

1. Unique board design:

Using the numerical simulation technology of ultra-fine mesh combined with the precise test measurement method, the heat exchange plate with superior flow and heat transfer performance is designed. The unique design of the plate grain can make the fluid at a lower flow rate can produce turbulence, greatly improving the heat transfer coefficient. The plate mold design is more reasonable, forming up to thousands of contact points between the plates, uniform pressure, high pressure resistance up to 25KG.

2. Advanced shunt zone:

The split-flow area of the plate is designed with streamline guide groove, which balances the difference of flow resistance caused by uneven fluid distribution in different flow channels, and avoids the disadvantages such as the decrease of heat transfer efficiency, pitting and dead Angle scaling caused by uneven flow distribution and flow dead Angle.

3. Super sealing gasket and groove:

Adopt stick - free snap type gasket, fixed firmly with plate, avoid pressure dislocation. And two seals are arranged between the hot and cold fluid, and the leakage area is in the middle. Even if a sealing pad is damaged, the leakage will not make the two fluids mix, but flow to the outside through the leakage hole.

4. The scientific designed framework:

The use of 5 points positioning suspension system, not only to ensure that the plate on the left and right positioning is accurate, but also to ensure that the plate can automatically lock each other when clamping, so in the plate reset can be easily accurate alignment, eliminate human operation error, so as to ensure the performance after the dismounting of heat exchanger, the service life of the gasket is more permanent.

The front and back baffles are cut by numerical control and formed in one time, and the surface is micro-forged to enhance the surface strength.

The locking nut and rolling parts are specially designed, and made of high strength, high wear-resisting and anti-corrosion materials.

|

Max Flow rate |

Caliber |

Single plate heat area |

Max Plate QTY |

Material |

|

0.1T/H |

19mm |

0.02m2 |

60 |

SS304 or SS316L |

|

2T/H |

32mm |

0.08m2 |

65 |

|

|

8T/H |

40mm |

0.12m2 |

100 |

|

|

30T/H |

50mm |

0.22m2 |

130 |

We can customize according the client requirement.