HSPS horizontal low-shear transfer feeding food grade pump stainless steel super low shearing grinding sanitary sine pump - excellent efficiency, high viscosity Best selection of super low shear feeding.

Tel:008618367778783 Email:sales@wzhongan.com

1. HSPS horizontal low-shear transfer feeding food grade pump stainless steel super low shearing grinding sanitary sine pump - excellent efficiency, high viscosity Best selection of super low shear feeding

2. 2. Super low shear feeding Although with a great deal of solid particle and fragile product A safe and no damage feeding can be provided.

3. 3. High viscosity performance reaches the limit of flowing capability can reach 4,000,000cps.

4. No pulse, stable feeding.4. Flow cubage adjustment precisely, without interference and shock.5. It can supply a stable product dose evenly.working principle

Working Principle: Sine structure, Low shearing/grinding

Main applications: Food, fruit, condiment, beverage, candy, meat, cosmetic, etc

Driver: Electric motor

Power Specs: Customized

Max.permissible fluid temperature: 120°C

Type of connection: Quick clamp, Flange, Thread, SMS, etc

Installation position: Horizontal

Main Material: SUS304 or SUS316l

Shaft seal type: Water cooling mechanical seal

Maximum drive rating: 15KW(20HP)

Maximum caliber: 152mm(6inch)

Maximum discharge-side pressure: 6Bar

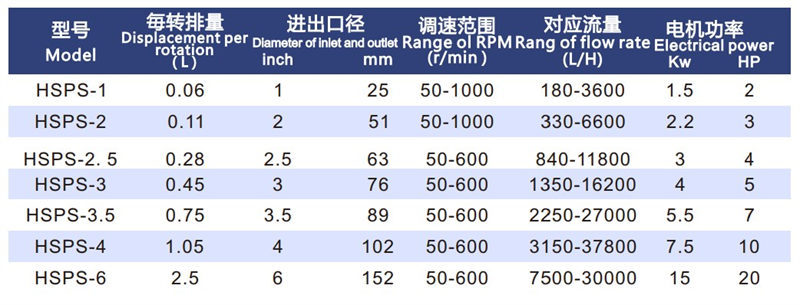

Flow rate range: 180-3000L/h

Working principle:

1. The sine wave shape of impeller means a cavity can be formed at every rotation (4 cavities can be formed every passing the lining space). This operation can "push" or "release" flowing products. The pump cavity is divided into suction chamber and extraction chamber by control panel to ensure pressure tolerances at exit and entrance. Meanwhile, control panel plays another important rote to lubricate the pump bearing by product in compulsion.

2. Sine pump: Special two sine-curve-like vane is taken, instead of rotor, epicyclic gear or piston, and it runs with a movable panel and a fixed line, forming a special volume pump and realizing liquid super low shear, without pulse feeding, although in condition of 10/15 bar back pressure (water feeding), there won't be any movement on pressure gauge.