Colloid mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size of a liquid suspended in another liquid. Colloid mills work on the rotor-stator principle: a rotor rotate at high speed.

Tel:008618367778783 Email:sales@wzhongan.com

Operation principle:

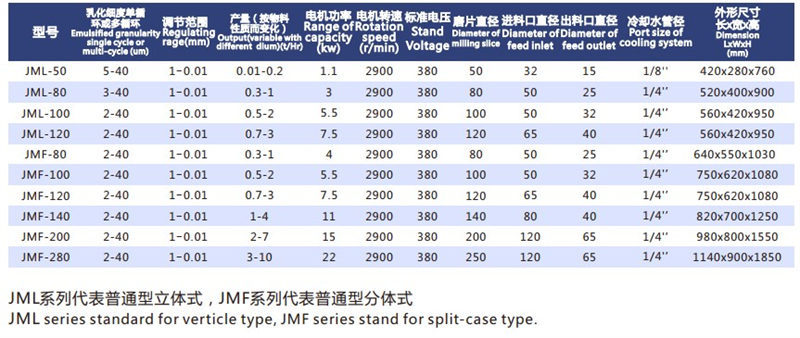

Colloid mill works with shearing, grindinghigh-speed stirring. Grinding process occurs in the relative movement between the two teeth with one revolving in high speed and another still, which makes the material between the teeth receive strong shearing and abrasion in addition to high frequency vibration and high speed swirl. The above forces effectively evenly disperse, emulsify, smash the material. JMF/JML is a new equipment that wet processed superfine grain, which is used for smashing, mixing, emulsifying and homogenizing various semi- iiquids, liquids and emulsion.

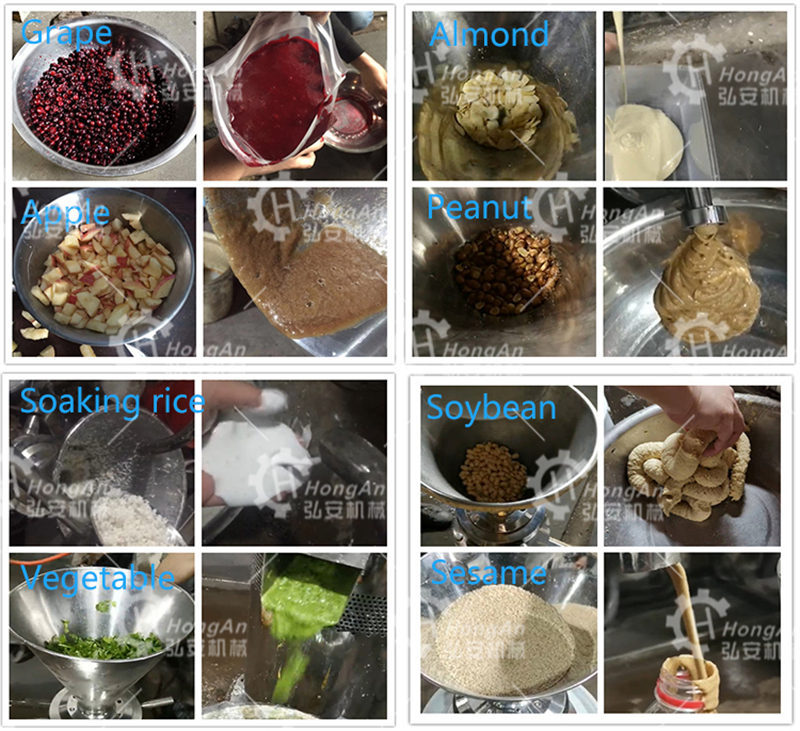

Application:

Food industry: dairy products,chocolate,soya sauce,jam,peanut butter,cream drinks and chemical industry:pigment,lubricating oil,spices,dye,emulcified asphalt,emulcified rubber,catalyst,paint coating and so on.

Pharmaceutical industry: cod- liver oil,confidentiality,athletes cream,queen bee,pollen daily chemical industry:shoeshine,toothpaste,cosmetics,balsam,soap,detergent and so on.

Other indurties: construction industry,paper making industry,plastic industry,battery industry and so on.

Raw material effect after processing.